Baja kit for KTM EXC/EXC-F *Required step

All light combinations come with a dedicated mounting bracket, harness and anti glare foam.

If you select the option "I will use my own lights" the kit will not come with any light brackets unless specifically requested. We only manufacture brackets for the lights listed below.

- Final price (tax excl.)

- €1,600.00

Products can be shipped with insurance.

Delivery through international shipping services

Baja kit for

KTM EXC/EXC-F

Designation: BR4

The best of both worlds!

Available now for:

2-Stroke EXC 150-250-300 models 2017 to 2024

4-Stroke EXC-F 250-350-450-500 models 2017 to 2024

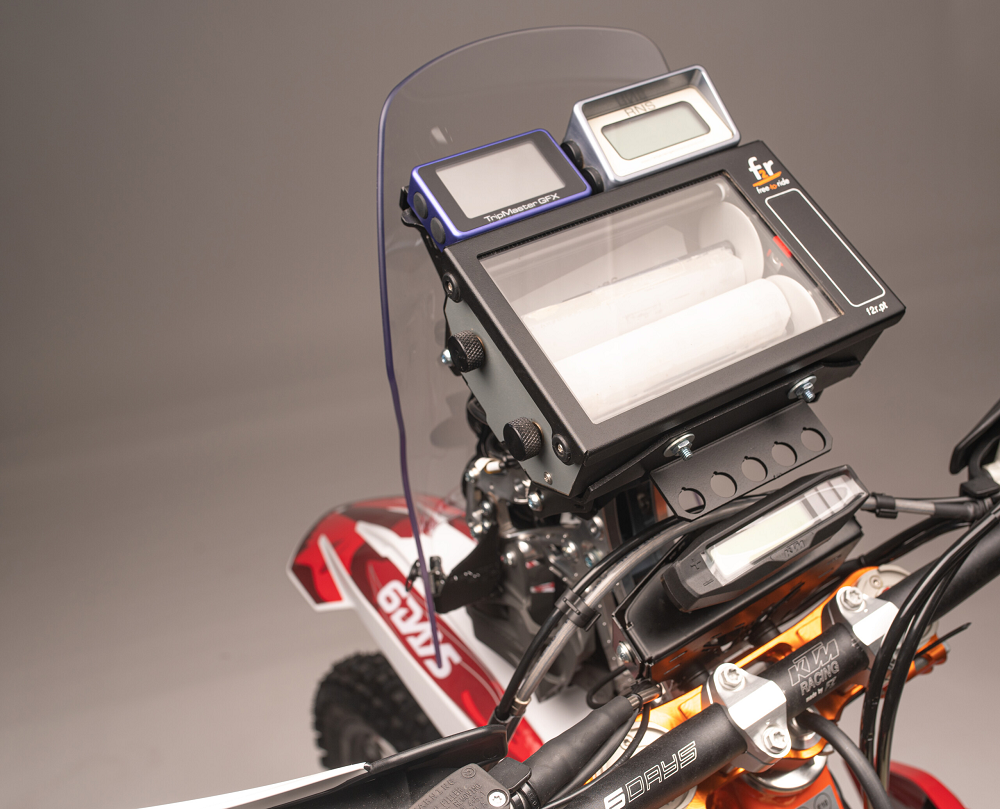

The most racer oriented Rally kit in the market!

A unique combination of the best parts from our Rally and Superlight kit to get you onto the podium.

The choice is yours!

Click on the ''COMBINED' button on the top left corner to see all charts in one.

What you see here is a spider (or radar) chart. We are comparing the OEM bike vs different Aurora Layouts that we have in our range. There are eight areas of interest.

1. Ergonomics. This is your instrument layout. Are they in a better position? Easier to see? Higher is better.

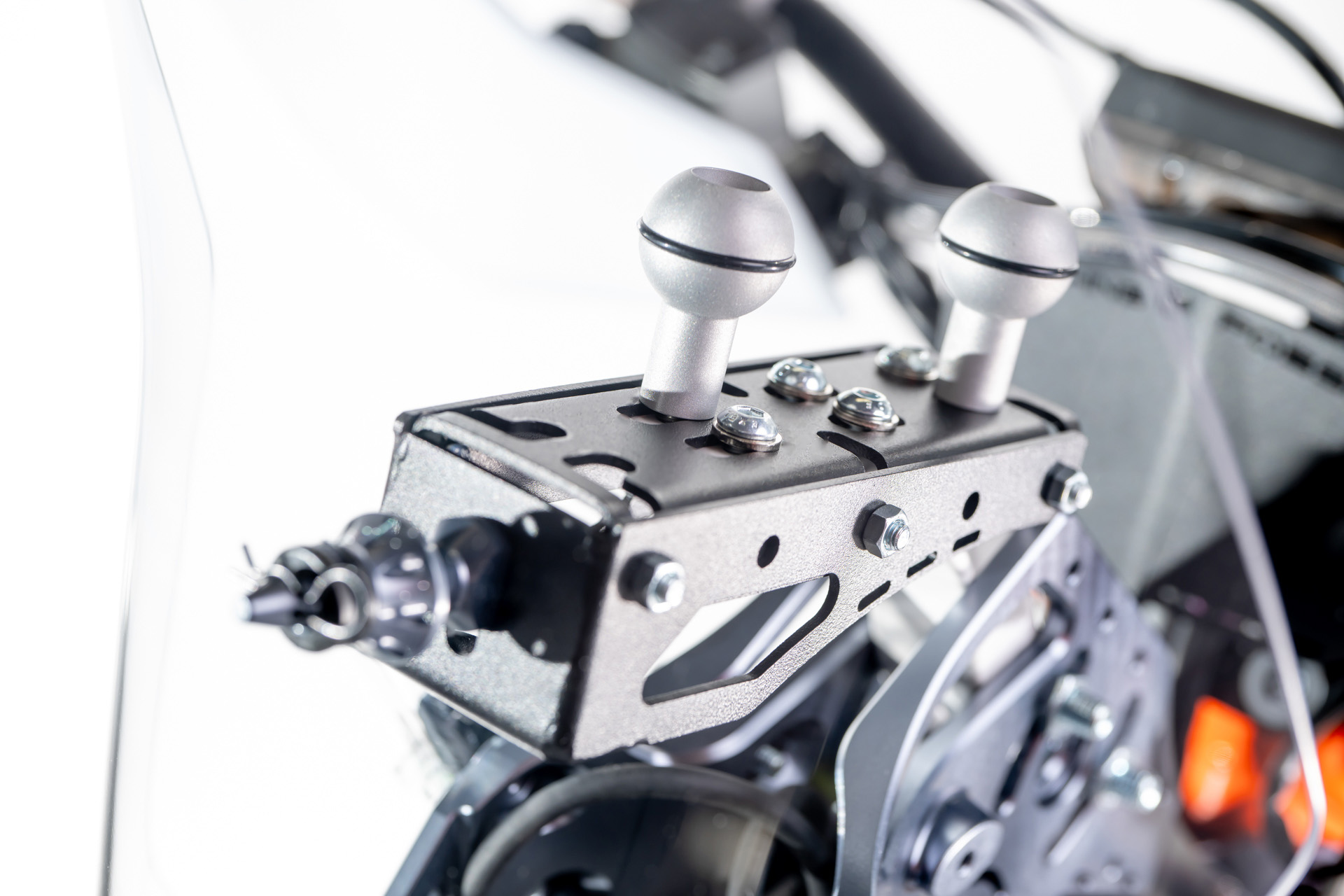

2. RAM balls. These little things will allow you to add from mobile phones to tablets!

3. Service. Is it quick to access the main areas of interest?

4. Lights. OEM lights are fully legal. In our kits not only you upgrade the lights, but you can install full off-road LED units for max performance.

5.Weight. That's a necessary evil. We remove and we add parts on the bikes and the net effect is sometimes a heavier bike, or in the case of our Superlight kit a lighter bike.

6. Safety System. The one and only Screen Safety System which will protect you during a crash!

7. Racing. How race oriented is each kit.

8. Iritrack. Can you install the FIM tracking device?

Choose your areas of interest and get the best possible solution! A full comparison can be found in the FAQ section.

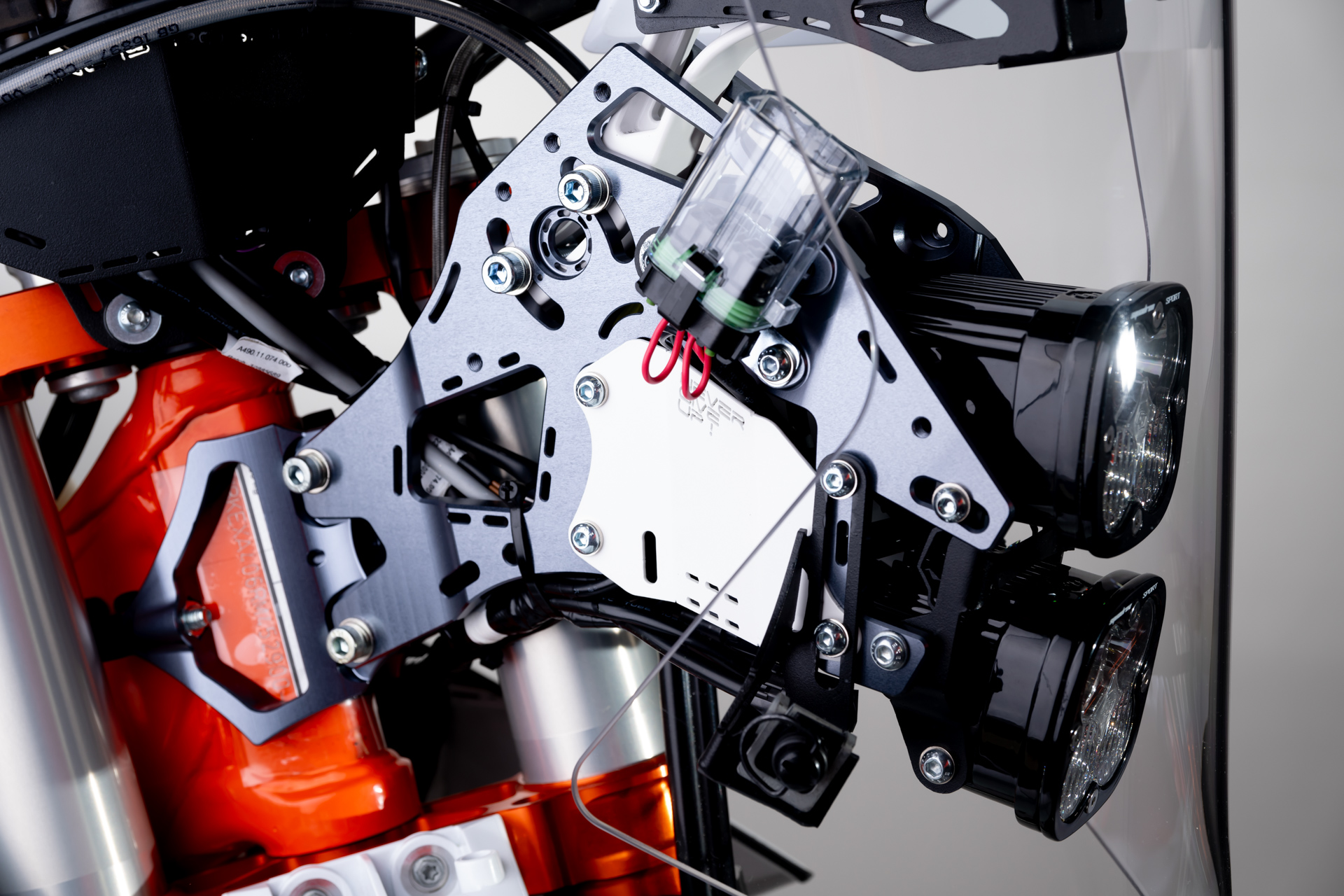

Frame Clamp

The CNC milled frame clamp has its roots in the legendary frame clamp that we designed back in 2016. With an unmatched record of zero failures since 2016. A clamp winner of international races in Africa and Europe and even up to Alaska in round the world trips, gives the riders the safety and security that they need during long distance trips.

The KTM/HQV/GasGas clamp (2017-2023) is a two-piece design, machined out of a 50mm solid block of Aluminium. It is the only frame clamp in the market that will protect your frame from being squashed during tightening. .

For the 2024 models onwards, we had to go back to the drawing board and create a beautiful single piece of aluminum which fits like a glove to the frame. The clamp is made out of Aluminum with a tool steel grade clamp part on the rear.

Depending on the model year you will receive the appropriate head clamp. (2017-2023 Design A, 2024- Design B)

*Pictures are indicative

Electrics

This kit would be nothing without plug and play electrics. All the cables are included in the kit, such as rectifier extensions, light harness and even a fully waterproof fuse box with a pre-wired harness for ease of use. This fuse box is the first available fuse box in the industry that is fully waterproof and for a good reason. Traditional fuse boxes are completely exposed on their rear side. Allowing moisture, dirt and other debris to reach the electrical connectors, slowly corroding them over time. Since these are not visible, it is a real challenge to trace the errors once they start. The fuse box that is included in the kit seals all the cable entries and the cover with proper, rubber seals, much like the waterproof connectors on our bikes. You can add up to four fuses and if you combine them with the long cover fuse box and with automatic fuses you will get unparalleled long-term reliability.

For the 2024 model we have gone ever further and also offer all the necessary extensions for the OEM speedo, brake switch and everything else needed. Always plug and play!

Ease of use

Nothing is easy when you are in the middle of Africa, North America, or Saudi Arabia. For rally riders time is vital. Racers and Travelers are very similar. A racer in the middle of nowhere, a traveler in the land of Mongolia. They all need to be safe and fix any issues as quickly as possible to reach either the daily bivouac or their daily destination. The Aurora screen is not attached to the sides of the bike in any way, allowing you to remove it with two ¼ turn bolts.

You can add the tank of your choice and the kit will not interfere with that. In addition, contrary to our 701/690 kits where the bike panels are changed to minimize the undressing time, in all the enduro bikes the side panels are a breeze to remove. So there is no need for a quicker system.

In the dedicated rally bikes, cabling goes through the tower. Once the rider needs to trace an electrical issue, he must undo half the bike to trace it. This is not only time consuming, but prone to error when things are put back. In our Baja kit, like in the Superlight, cabling can be accessed quickly and easily.

Mechanics

Adding parts on your bike, means adding weight. But when the parts are designed with that in mind, the effect of this added weight is negligible. The assembly’s center of gravity is chosen carefully so that (1) it is as close as possible to the bike's stem and (2) if you add anything to the dedicated position (under the tower), it will have a minimal effect on the bike’s behavior. To optimize that behavior the assembly is analyzed as a system, comprised of different parts. A very light tower with a heavy tablet or Navigation gear on top, will have the opposite effect. An unstable structure.

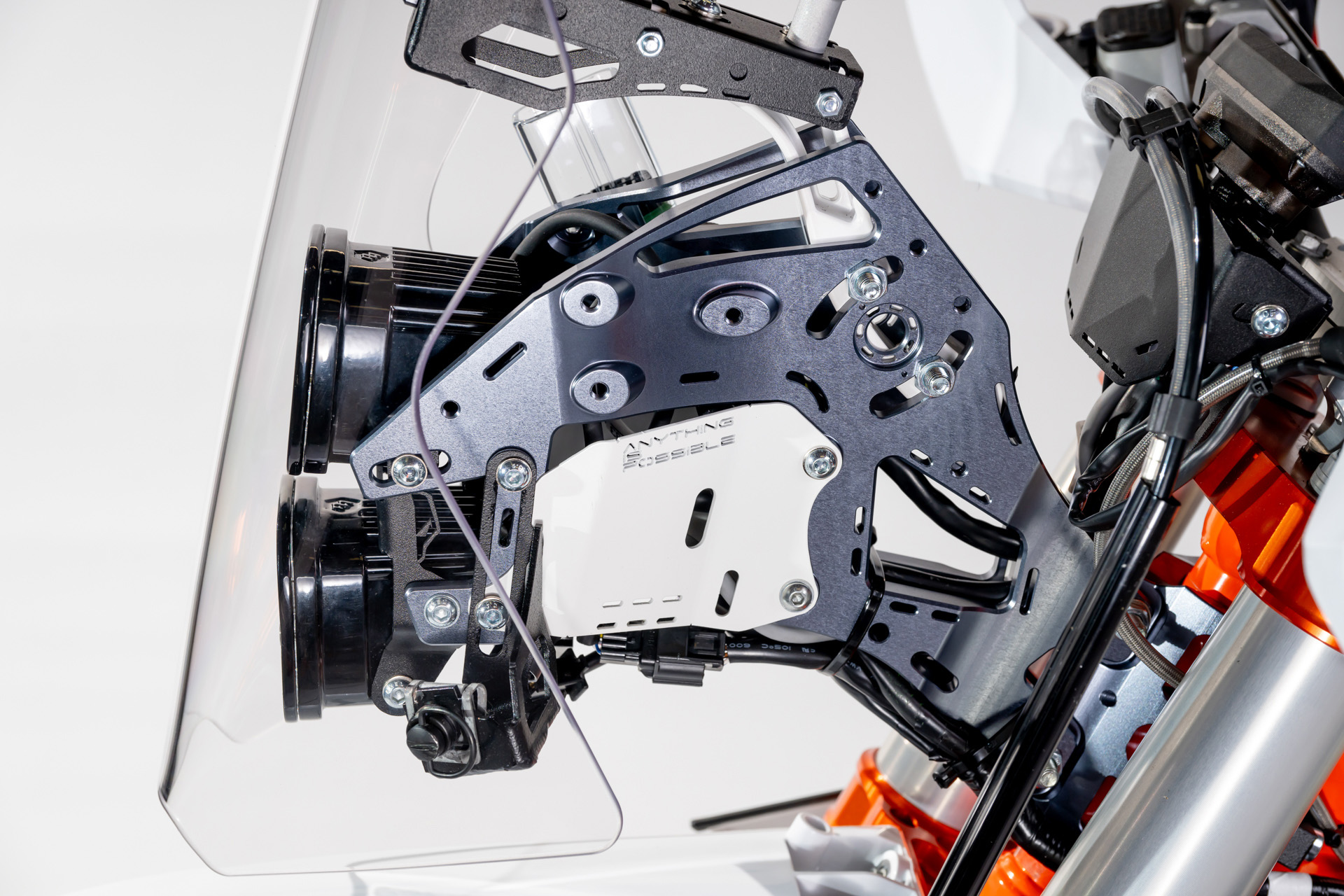

All our tower configurations were analyzed to perfect the system’s center of gravity. Add the iritrack or a full navigation setup, the center of gravity of the system will stay low and as close as possible to the bike, minimizing the effect, allowing you to reach your destination stress-free and race with confidence. The Aurora screen is further optimized for additional protection of the rider and the equipment. The main aluminum parts of the tower (sides, light support, and middle rib) weigh 1.4kg!

How it's made

High speed accelerometers are used to create a library of data in different scenarios. Racing, Traveling, Commuting, Motocross etc. All these data from our database are used by our engineers to create virtual simulations of the worst-case scenarios, based on values from out data logging activities. The parts are put through virtual testing before they even get manufactured. Static and dynamic analyses, impact, and fatigue tests, as well as topology optimization are all performed on high end PCs dedicated to Computer Aided Design (CAD). If the parts fail at this stage, there is no reason to even turn the CNC milling machine on.

Having optimized the parts, 3D printing commences. All the parts are printed in high quality Alumide (Polyamide with a low percentage of aluminum particles). This allows us to have a functional model to test on the bike and perfect he ergonomics, cable routing, and test the bike in real time without producing expensive aluminum prototypes. The designers make the final touches at this stage, as the printed parts can be drilled and threaded. For the tower alone, both the tower and the frame clamp, went through 12-15 iterations to get to the final, optimized design that you see in the pictures.

And why is this important? Because if a tower has endured one Dakar, this does not mean that it can endure a second one. Fatigue life of metals is measured in millions of cycles and one rider cannot simply reach those numbers during a rally. What is important is that all our simulations are backed up by real testing and then we also see if the software analysis predicted everything as it should .If not, we re-adjust the model to get the real life results.

Traditionally spacers are used in all the navigation towers, not only to connect the pieces together, but increase the stiffness of the assembly. Optimizing the stiffness by designing each part individually in 3D, spacers are not necessary anymore. The main tower is only, 3 parts. Easier to maintain, access and service.

Tower shape

The CNC tower is designed from scratch, and it has a characteristic, ‘crane’ like shape. Sheet metal towers have a different design. They are wider on top, in order to increase their moment of inertia. A property that defines the capacity of a cross section to resist bending or buckling. Although the above holds true, making any tower, wider on top will also make it more unstable and special design practices must be used to counteract that effect. The uniquely shaped CNC tower, allows the designers to keep the width of the tower to the minimum, resulting in a structurally stable assembly which will have higher resistance to bending or buckling.

Manufacturing

There are different manufacturing methods in all the parts that we have on our motorbikes. Welding, Laser cutting, Sheet bent parts, 2D milling, 3D milling and others. 3D milling is one of the most complex, but also one of the methods that produce high quality parts. The head clamp and the navigation tower are produced by 3D milling, allowing us to optimize the thickness of the material, maximize the strength and minimize the weight of both parts. Machined out of a solid block of aluminum (40 or 50mm thick!) , these parts are strong where they need to be, while as the assembly is simpler for the end user.

Aurora PET windscreen manufactured by Puig

CNC Navigation tower with brackets and all electrics

Up to 7 Different light combinations

What's included in the kit

*When additing lights the kit comes with the light dedicated bracket, harness and anti-glare foam.

**The kit comes with a dedicated headclamp and extensions for models (2017-2023) and (2024-).

Versatility

More and more people choose their enduro bike for traveling. Longer suspension travel, lighter and with better off road capabilities than their adventure equivalents, more and more enduro bikes are equipped with soft luggage to conquer the Trans America Trail (TAT) and the Trans Euro Trail (TET). Occasional racers also choose their enduro bikes to race. Some of them even run the Dakar. In sheet metal towers it is not advisable to add weight on them. With the new CNC tower, it is a whole different world! Leave it light and simple.

We give you all the tools to create your dream rallying or adventuring machine. From up to 8 different light combinations and infinite room to attach all your gear and equipment.

Add your toolbag with a full set of tools. A small adventure raincoat? No problem. Need an emergency kit? Done! All of these, or a combination of the above can be installed in the CNC tower. Below you can see the 12 configurations that we came up with, and that is without the digital setups and the full racing modes. This tower can take you from Dakar to Mongolia, and then back. Just choose your personal configuration and off you go!

Compatibility

2 Stroke: EXC 150-250-300 models 2017 to 2024

4 Stroke: EXC-F 250-350-450-500 models 2017 to 2024

Disclaimer

Despite every effort to provide accurate images of each product’s color and design, actual colors and design may vary slightly, due to different device screen settings, the lighting in the installation location, slight differences in product finishes over time and other factors. Please contact Aurora Rally Equipment should you wish to confirm your final choices.

You may need to remove the charcoal canister in order to install this kit.

Product Details

Data sheet

- Rally kit features

- CNC Headclamp

CNC Nav Tower

GPS backplate

RAM mount

Rally backplate

Street legal lights - Motorcycles

- KTM EXC/EXC-F

- Custom product layout for kits

- Yes

Crossselling Products